Sai Ram Traders

Services

Our Services

Sai Ram Traders, Bengaluru, offer wide range of services which includes Chemical Tanks, Centrifugal Blower, Scrubbers, PPH Round Tanks, Fabrication, Plastic Welding and more.

1. Chemical Tanks

Sai Ram Traders, Bengaluru offer wide range of PPH, PVDF Chemical Tanks Services for our customers across the nation. We offer high quality Chemical Tanks with numerous features like good water flow system, inlet, drain, overflow features, chemical resistant and corrosion resistant, lightweight and more. Our FRP Tanks hold chemicals including sodium hypochlorite, sodium hydroxide, aluminum sulfate, coagulant and more. We supply high quality international standard PVDF Chemical Storage Tanks which are used for storing many types of liquids and chemicals. Our Chemical Tanks are designed with robust parameters, chemical tanks solutions which are known to be leak proof, immune to corrosion and low maintenance. We also customize Chemical Tanks as per the specific requirements of the customer.

Chemical Tanks are specialized storage containers used to hold a wide variety of liquids, including petrochemicals, acids, and other industrial chemicals. These tanks are designed to safely store and transport chemicals, often requiring specific materials and features to ensure containment and prevent leaks or spills.

2. Centrifugal Blower

Sai Ram Traders, Bengaluru is one of the leading Centrifugal Blower manufacturer, supplier in Bangalore, India. Our Centrifugal Blower Fans and Blowers, both pre-engineered and custom, made include backward inclined fans, backward curved fans, radial tipped fans, material handling fans, high-pressure blowers, and other Centrifugal Fans and Blowers for Industrial application.

Centrifugal Blowers are Strictly Tested for Dynamic Balancing, Static Balancing, Alignment, Speed, Air Flow, Static Pressure, Noise and Vibration. Accessories such as Vibration Pad, Inlet/outlet Damper, Lining, Acoustic Box etc. are available as per requirement.

Product Details:

Centrifugal Blower material: SS MS PP FRP (Fibre-reinforced plastic). Capacity Range: 150 CMH to 500,000 CMH

3. Scrubbers

Scrubbers are highly efficient Air Pollution Control Equipment used to remove fumes and gases from industrial processes. The process takes place by 'Scrubbing' the pollutants by contacting them with a scrubbing media (either wet or dry) thus resulting in a residual exhaust of negligible particulate size.

We thus categories them into dry and wet scrubber systems. Gases are employed in manufacturing processes in numerous production plants and research facilities. Some of these gases are flammable or corrosive, and some are even toxic. Our systems remove such substances from exhaust air to protect people and the environment. Scrubbers have served the various Gas Cleaning Plant, Fume Treatment, and Gas Treatment application, E.g. HCL, CI2, SO2, H2S, NH3, HBR, HF, NOX, PCI3, POC13, CH3SH, Br2, CoCl2, SOCI2 etc. offers PP FRP ,MS ,Scrubber & Scrubbing System, with precised design as per requirement in various Composition of Material.

Product Details:

Scrubber material: PP AND PPFRP. Type: Vertical / Horizontal / Dry /Wet. Molding: Extrusion Molded. Capacity Range: 150 CMH onwards.

4. PPH Round Tanks

PPH (Polypropylene Homopolymer) Round Tanks are versatile storage solutions used in various industries for storing chemicals, water, and other liquids. They are particularly favored for their strong chemical resistance, ability to maintain purity, and suitability for moderate temperatures

Key Applications of PPH Round Tanks:

Chemical Storage: PPH tanks are ideal for storing highly corrosive chemicals, acids, alkalis, and solvents, making them suitable for industries like chemical manufacturing, electroplating, and pickling.

Water Storage: They are used for storing water, including potable water, ETP water, STP water, and DM water.

Food and Beverage Industry: PPH tanks can be used for storing and processing food and beverage products.

Industrial Storage: They are used to store various liquids, including petroleum products, fuel, and other industrial materials.

Holding Tanks: In water and wastewater systems, PPH tanks serve as holding tanks for storing wastewater, housing pumps, and providing temporary storage during peak periods.

Pharmaceutical Industry: They are used for storing and processing pharmaceutical products and solutions.

5. Fabrication

Sai Ram Traders, Bengaluru offer state-of-the-art Fabrication Services intended to fulfill the various requirements of customers across the nation. We make use of latest technology, precision engineering and high quality raw material in producing custom-built components meant to clients requirements. We follow the Standard Quality Policy in fabrication to ensure genuine, precise and proficient final product.

We have high skilled team of experts who takes care of CAD design of models and drawings, raw material preparation, laser cutting, CNC machining and plastic welding, bending, turning and drilling to form different shapes like rods, pipes and sheets. The fabrication process also includes mechanical / custom assembly, sanding, polishing and surface treatment to smooth out rough edges and surfaces and high quality control testing, dimensional inspection and performance testing before delivery of the finished goods.

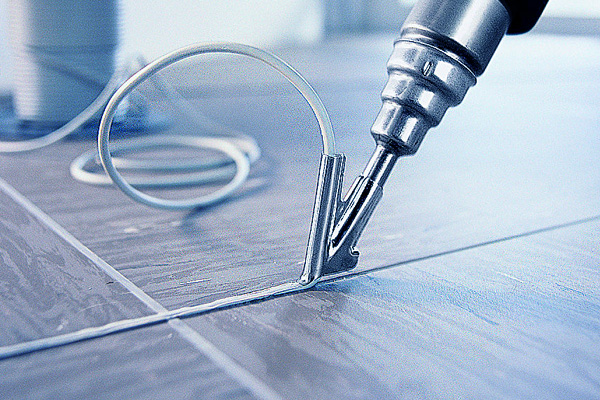

6. Plastic Welding

Sai Ram Traders, Bengaluru offer wide range of Plastic Welding Services to our renowned customers. Plastic welding keeps the environement clean, protect workers and has many applications like Piping, Boxes & Trays. We also supply plastic welding rods and offer an onsite plastic welding services at customers premises. Sai Ram Traders, Bengaluru offer wide range of Custom Plastic Welding techniques and methods which includes Hot Gas Welding, Extrusion Welding, CNC Butt Welding and more.

Plastic Welding is a process of uniting softened surfaces of materials, generally with the aid of heat. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods.

Plastic Welding Advantages

Plastic Welding offers advantages like strong, permanent bonds, air-tight seals, and the elimination of fasteners or adhesives.

Products Range